News新闻动态

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > News

TPR injection molding should be prepared before what

2019-07-29 09:41:00 admin

According to the characteristics and feeding conditions TPR material, general appearance and response process performance TPR material before molding for testing. TPR pellets often contain different levels of moisture, flux and other volatile low molecular weight compounds, especially those with a tendency TPR hygroscopic moisture content always exceeds the limits allowed by the process.Therefore, the processing must be dried before processing, and measuring the water content. TPR at high moisture content requirement of 5% or less, or even 2% to 3%, so commonly used vacuum oven dried at 75 ℃ ~ 90 ℃ 2 hours.

Already dried material must be properly sealed to prevent the material from the loss of moisture in the air and then drying effect, for the use of the drying chamber hopper can be continuously provide dry hot material injection molding machine, to simplify the job, to keep clean, improve quality, injection rate increase are favorable. Drying hopper loading capacity generally take 2.5 times hourly quantity of injection molding machines.

Purchase of new injection molding machines need to be changed early in the production of products, the replacement of raw materials, exchange or finding plastic in color decomposition phenomena need for the injection molding machine barrel for cleaning or washable before using, or. Washing machines generally use heating cylinder barrel cleaning method. Cleaning materials for general use of plastic materials (or plastic recycled materials). For TPR material, the processing of the new material available displace transition purge

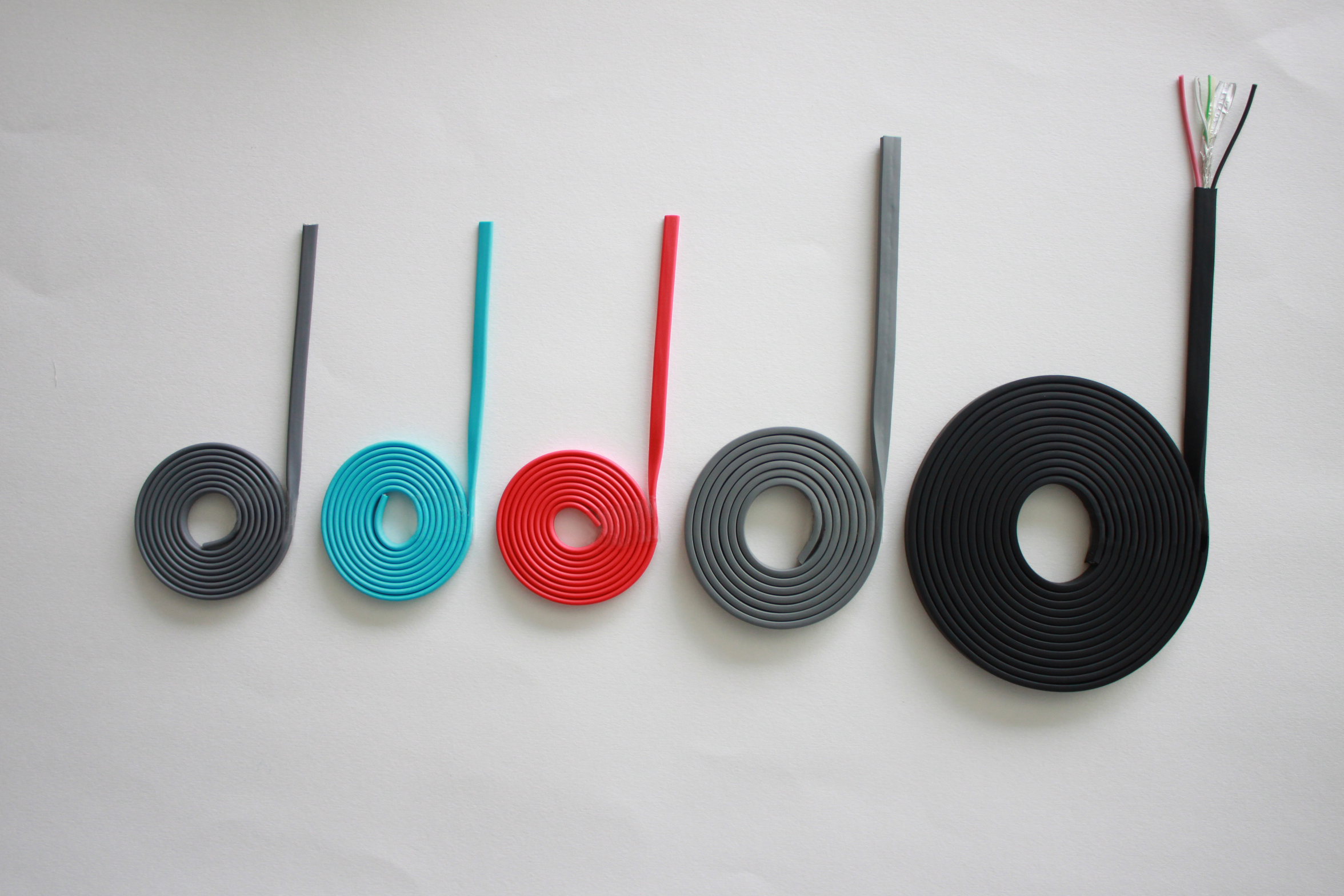

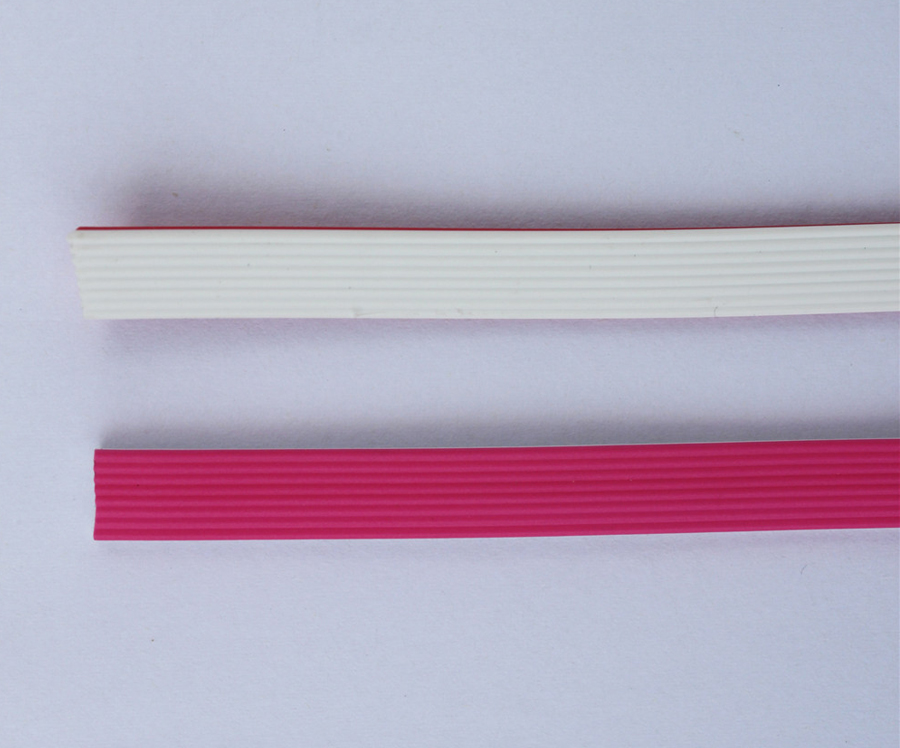

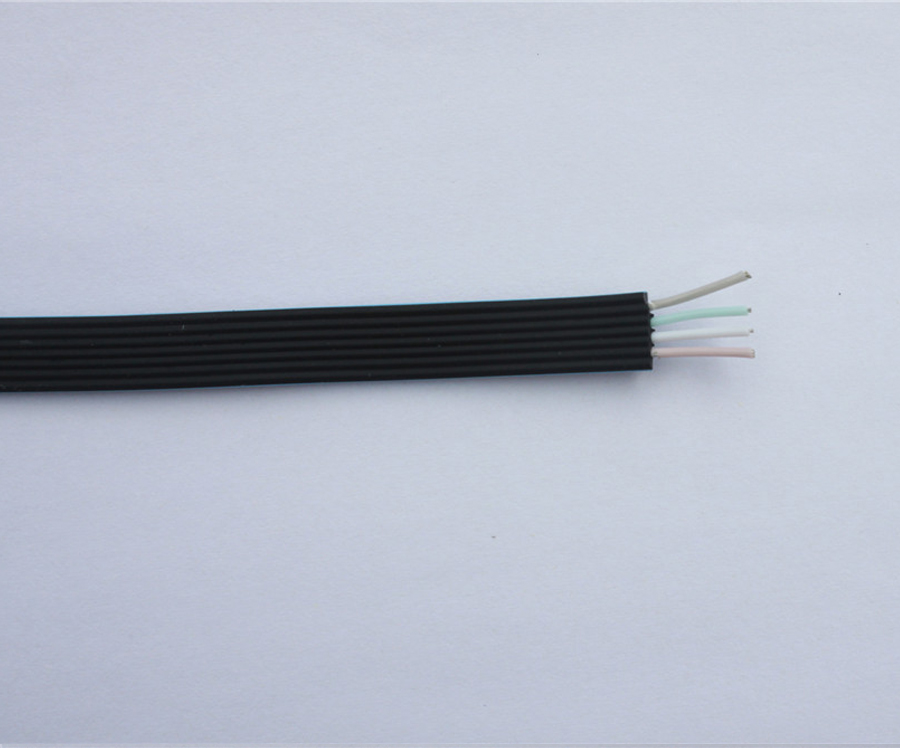

Recommended Products