News新闻动态

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > News

TPE thermoplastic elastomer hardness range is much

2019-07-30 09:45:00 admin

Due to the rapid development of TPE thermoplastic elastomer, a growing number of manufacturers have gradually started to replace the TPE thermoplastic elastomer rubber and PVC, silicone and other products. The hardness of the TPE thermoplastic elastomer, mainly refers to the product with a product parameters, so for TPE thermoplastic elastomer industry still do not understand people who may not know what the hardness is, do not know the scope of it is. Following small to address these issues in detail to tell you about:1, TPE thermoplastic elastomer Hardness:

Hardness and other important physical properties related to a variety of different measurement scales and hardness as well as relationships with other material properties, when discussing hardness may be confusing. In selecting a thermoplastic elastomer (TPE), the hardness of the material is often one of the first indicators to be considered.

2, TPE thermoplastic elastomer hardness measurement:

This instrument uses a sharp indenter and elastic strong spring. TPE using softer Shore hardness less than 00 Shore A scale measuring A5 material. Most soft gels and soft foam rubber Shore 00 scale using a measurement.

3, TPE thermoplastic elastomer hardness measurement methods:

Most materials can withstand the initial pressure, but over time, due to the occurrence of creep and relaxation but will yield. Hardness readings can instantly read, can also be read in a certain delay after a certain period of time, usually after 5-10 seconds to read. Instant readings usually show a higher reading than the delayed readings. Delayed reading and not only for the hardness of the material in terms of its resilience, are more representative. Weaker, less flexible materials, are relatively strong, relatively resilient material is more prone to creep. Hardness general report use the degree after 10 seconds.

4, different applications of different hardness mining

(1), the requirements for different product applications TPE materials are also different, usually 10 to 40 degrees to a low hardness, normally used in some soft contact requirements for products, such as medical products, some high-end sports equipment handles, and other electronic products The packet of plastic thickness of these products is relatively large, can reach 3 ~ 10mm.

(2), hardness 45 to 65 degrees, medium hardness, normally used in some electric hand tools, kitchen utensils, knives, scissors, screwdrivers, household tools, luggage accessories and other plastic packages, we hand skin hardness is usually around 55 degrees usually chosen close to the hardness of the skin and manpower to get the best contact comfort.

(3), hardness 70 to 90 degrees to a high hardness, generally used in encapsulating surface relatively flat, relatively large surface, thin injection molding products, such as electronic appliances, mobile phones, tablet computers ,, communication instrumentation products plastic bag. Usually this type of thin products, planar, large areas of encapsulated products need TPE having high fluidity, low shrinkage, suitable surface hardness characteristics, therefore, must be used to achieve high hardness of TPE.

Finally, we learned that the thermoplastic elastomer TPE wide range of hardness, from super soft to 90A, with good resistance to UV, weathering resistance, high temperature, long-term for the outdoors. So that different products should be good choice for their hardness.

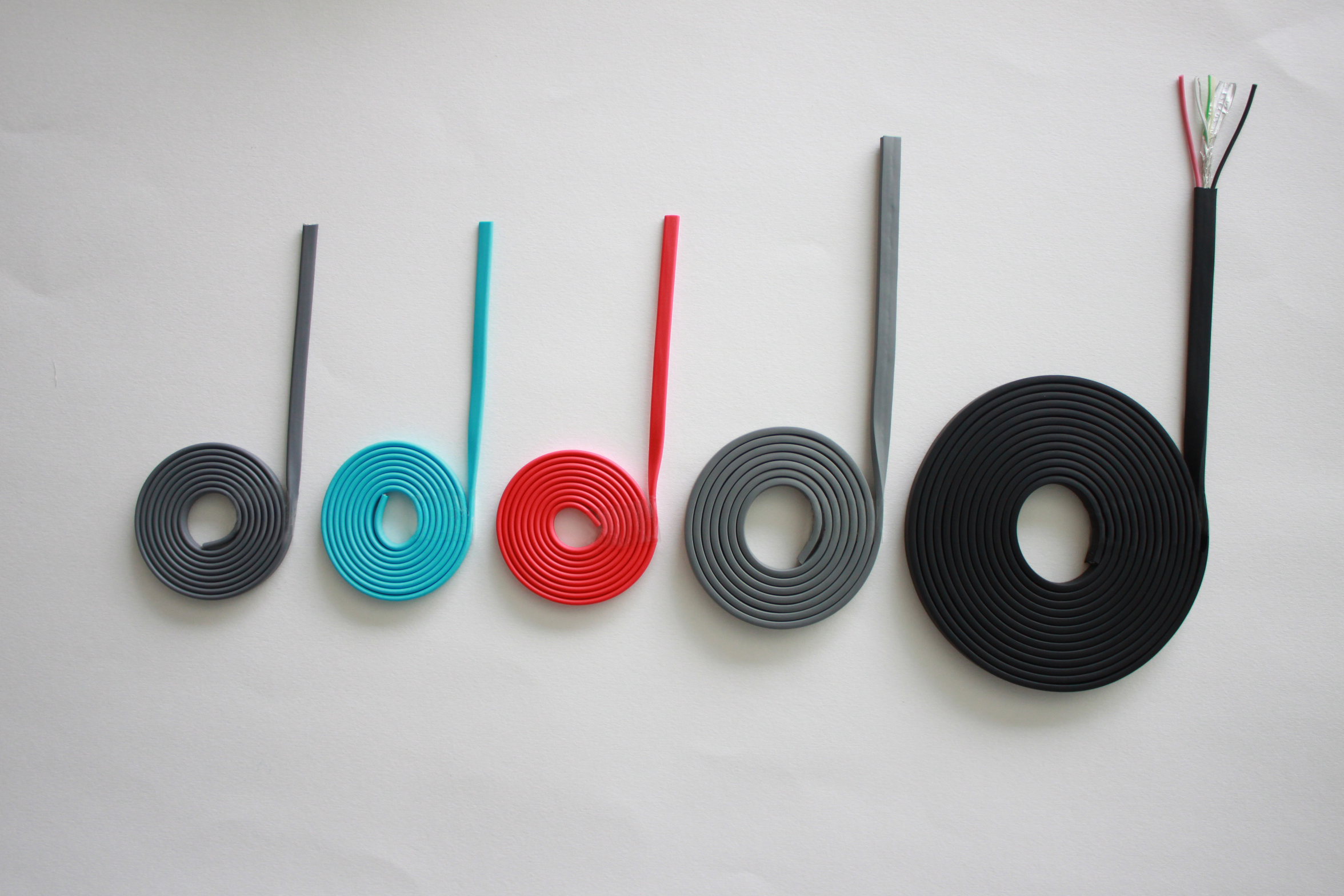

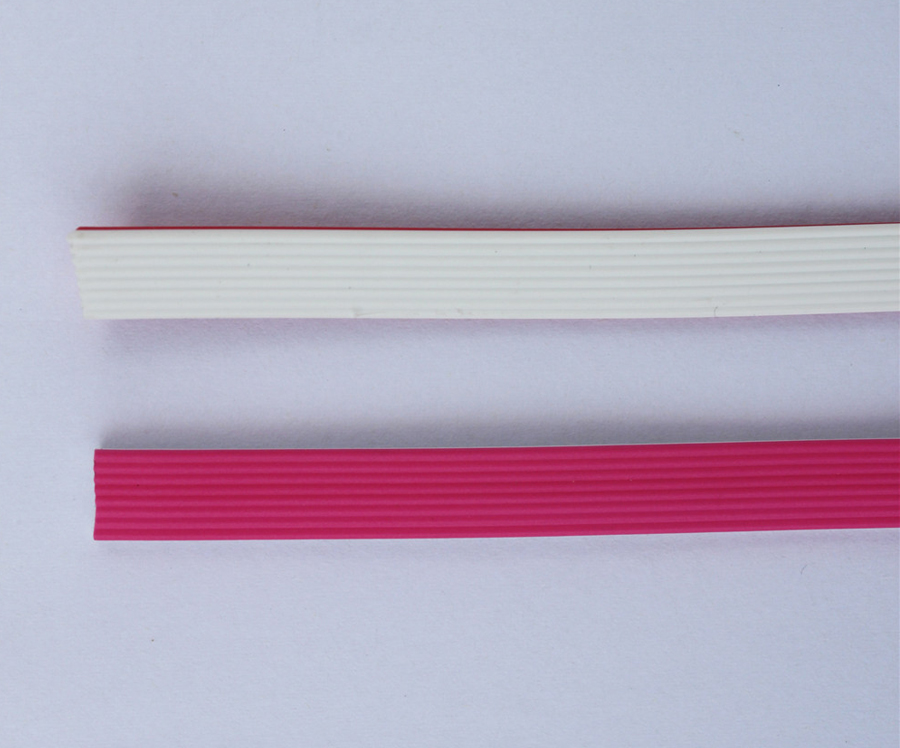

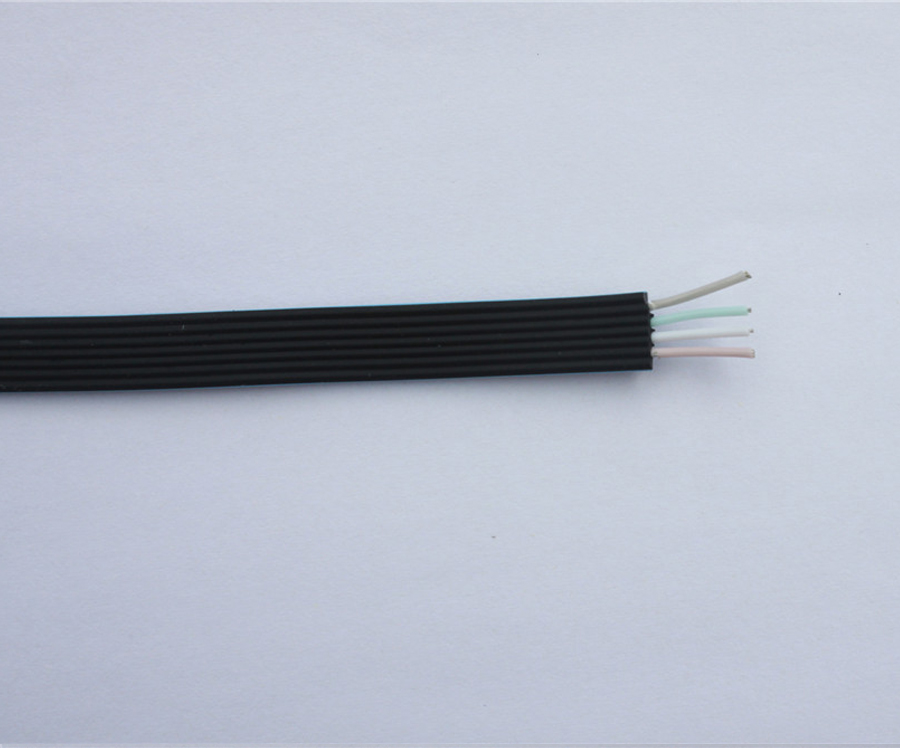

Recommended Products