News新闻动态

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > News

TPE encapsulated Problems

2019-07-29 09:26:00 admin

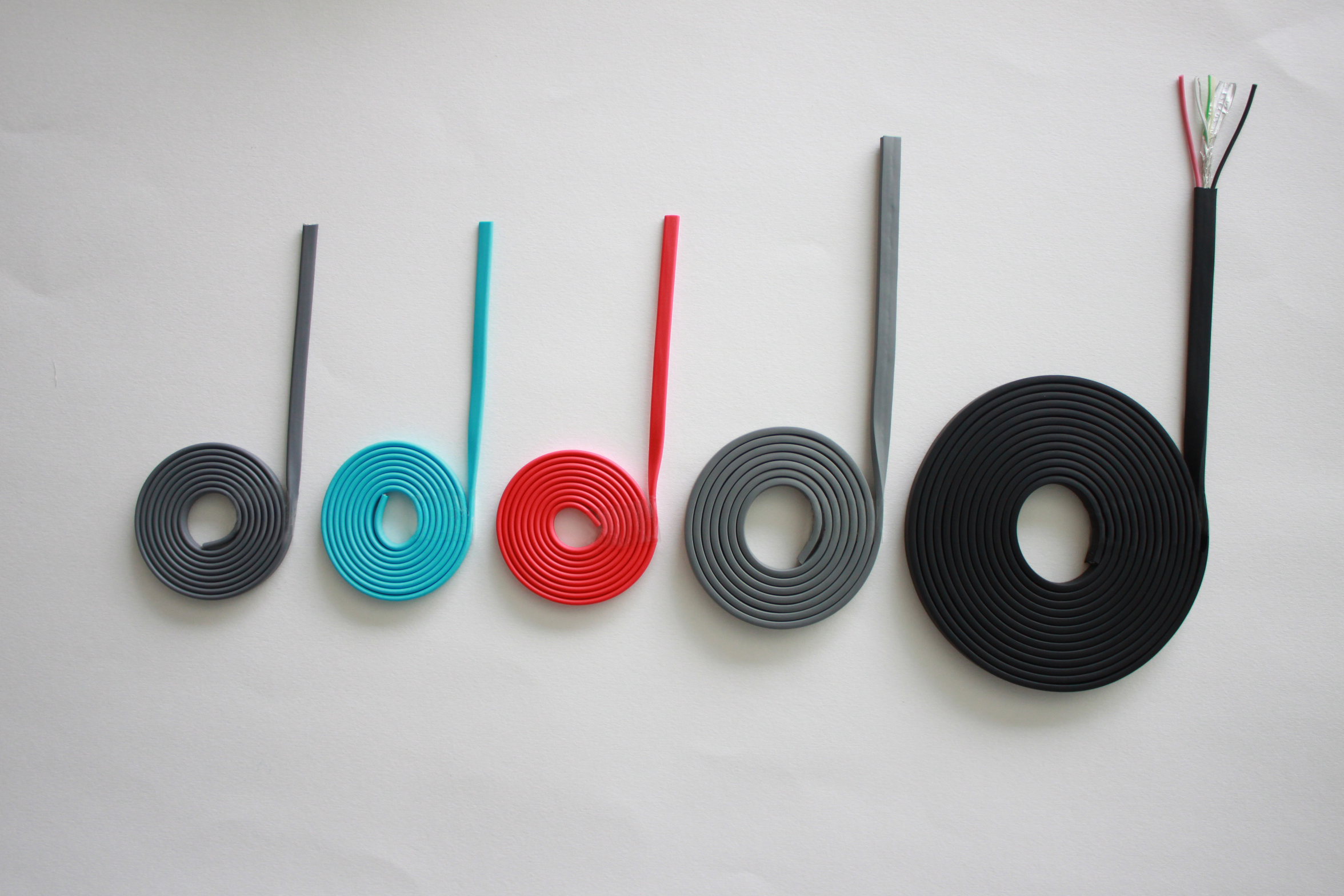

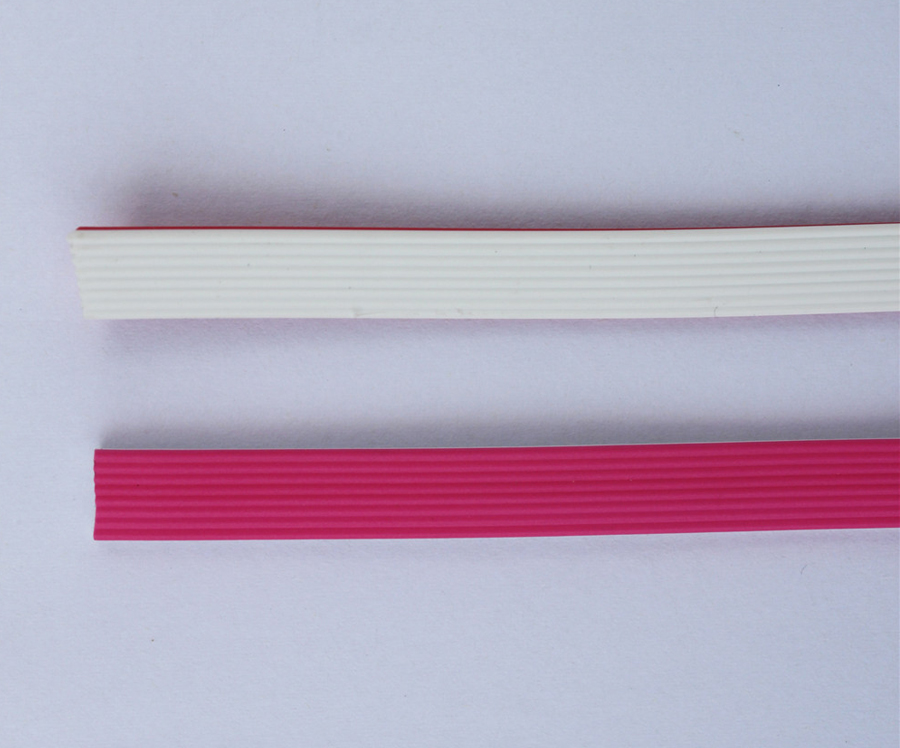

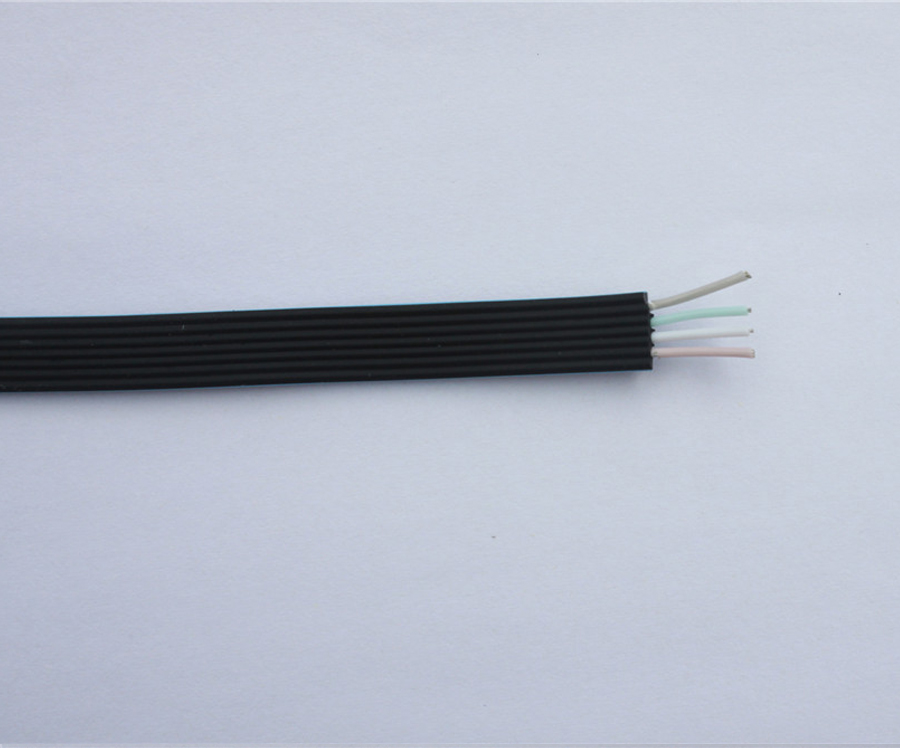

An important application field of thermoplastic elastomers TPE - encapsulated PS structure, usually we see the most is the TPE plastic bag ABS, TPE plastic bag PP, like the market the most is the handle TPE plastic bag we've seen, play a non-slip, soft touch effect. TPE overmolded plastic bag processing parameters need to pay attention to some of the following conditions:TPE material encapsulating electric toothbrush:

1, the compatibility with the PS TPE structures need matching, molecular solubility close to compatibility molecules was relatively good;

2, in the design of the need to avoid sharp corners, to ensure good contact with TPE and hard plastic parts, to enhance the bonding effect;

3, by suitable exhaust in order to avoid leaving the mold cavity gas;

4, so that the thickness of the touch TPE expected to reach equilibrium;

5, keeping the temperature TPE melt to ensure adhesion;

6, TPE overmolded material required drying material reprocessed to reduce the product surface waterlines to obtain the effect of surface color uniform;

7, its masterbatch carrier resin selected are compatible with the TPE materials and structures;

8, smooth surface for special treatment, the purpose is to increase the contact surface of the adhesive soft and hard plastic, strengthen the bonding effect;

9, TPE should have good liquidity, due to the layer thickness and TPE package size ratio is small, TPE usually requires passing through a long path and thin-walled area to charge into the mold.

10, TPE flow length / thickness ratio of less than 150 articles: 1;

11, use a good adhesive.

- Previous: no

- Next:TPR injection molding should be prepared before what

Recommended Products