News新闻动态

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > News

TPE material how to choose

2015-09-10 09:57:02 admin

TPE material comes everyone is familiar with, will often use the TPE material products in our lives, such as toothbrushes, racks, kitchen supplies, etc. are TPE material products, TPE materials are blended polymer alloy, different industries or areas TPE material for the physical performance requirements are different, so, how do we choose TPE stuff? Wang TPE material below the plastic manufacturers to share with you.According to the function selected:

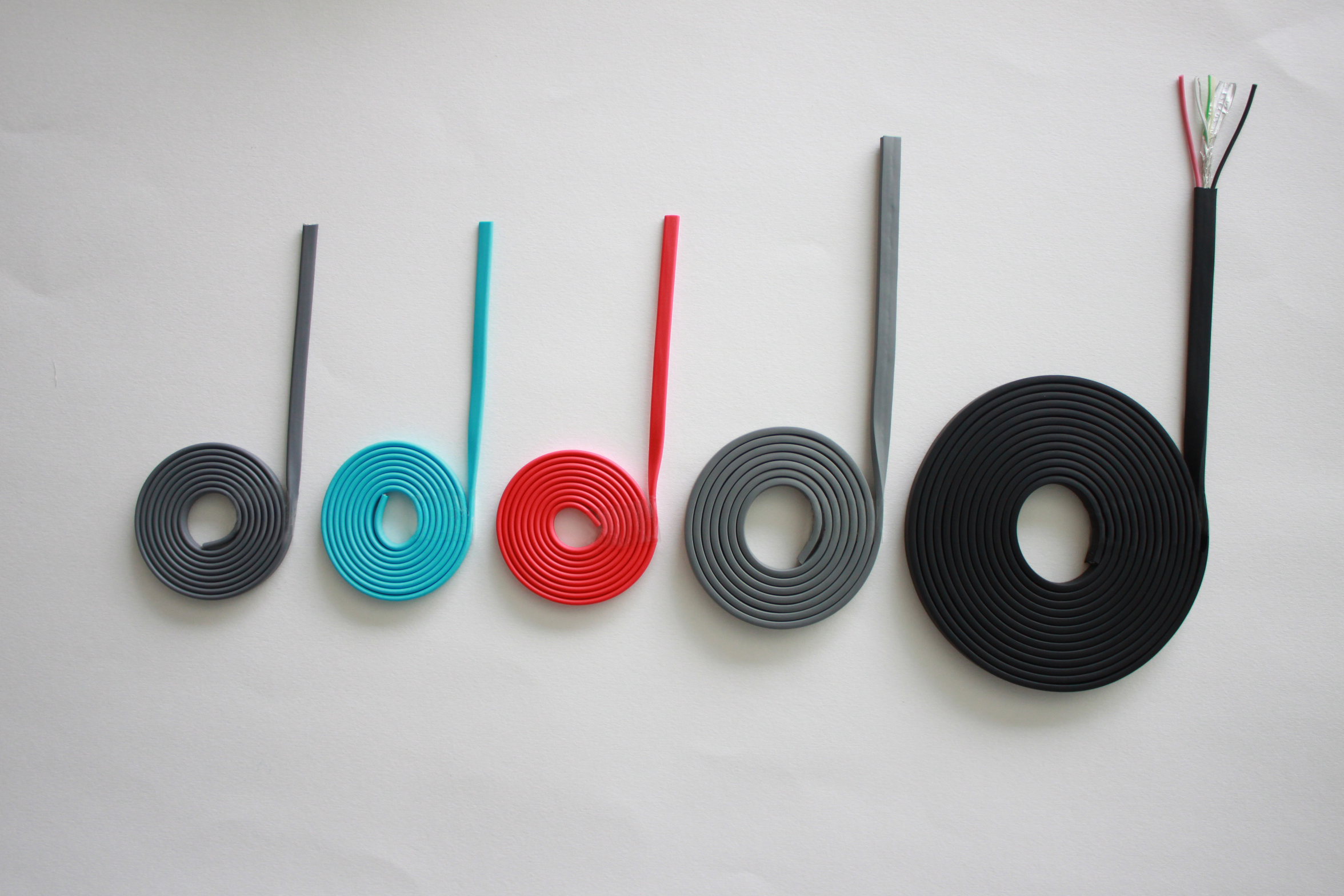

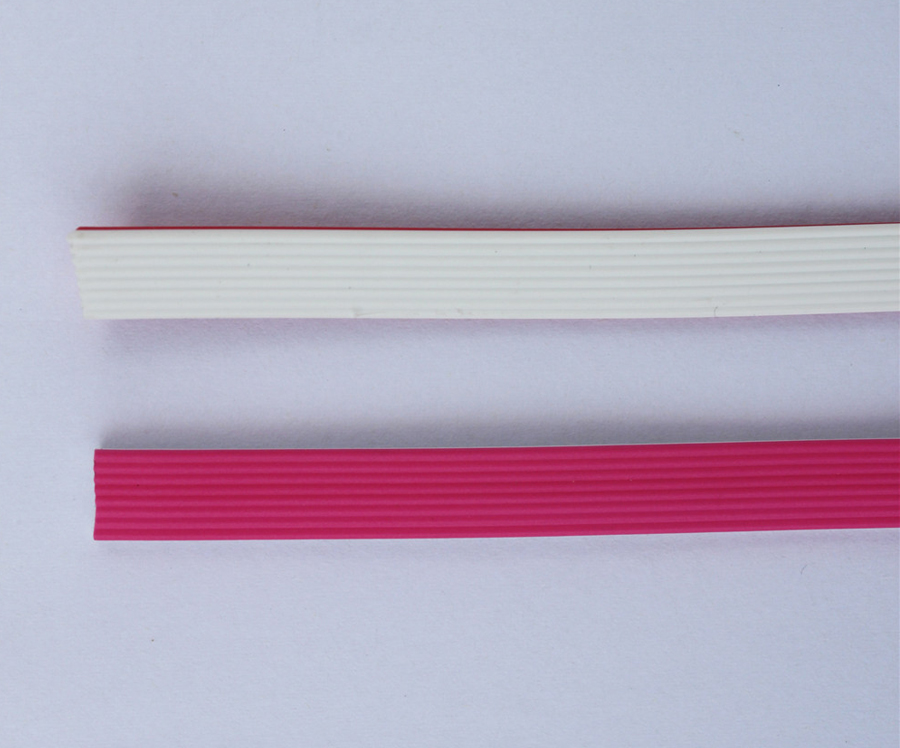

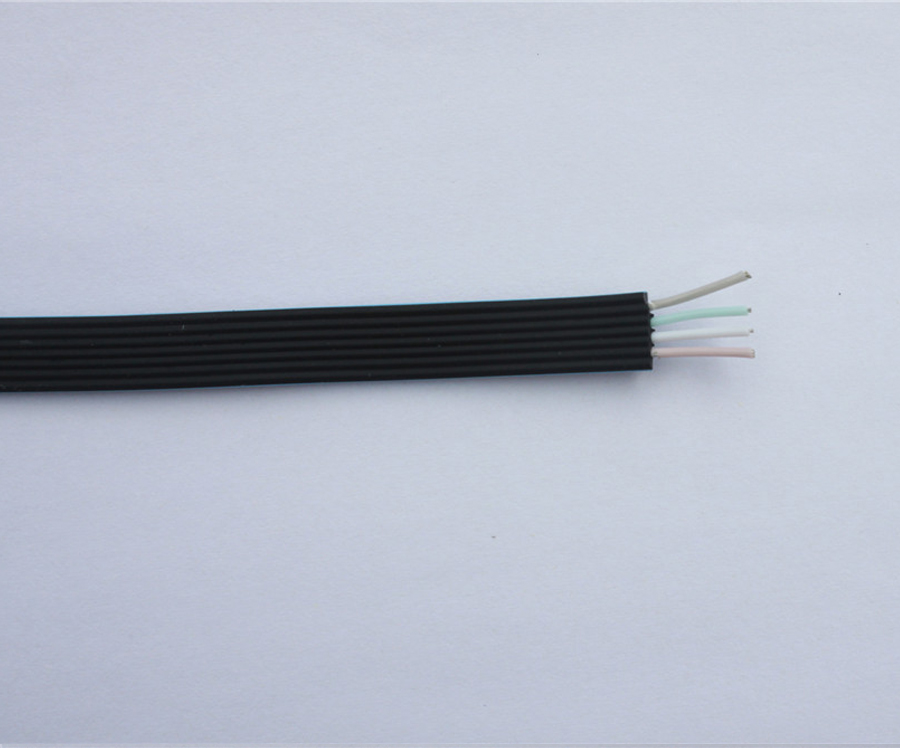

TPE materials require different products are different, such as the handle handle products, the surface scratch white, or even require smooth, dry, non-stick dust wheel wear better class product requirements, some of the wires such as headphones, cord, etc. need matte effect, require screen printing LOGO and text, some electronic wire industry, automotive industry applications TPE, TPR products, fire retardant may have higher requirements.

Temperature asked to choose:

TPE material of some electrical and electronic industry applications TPE products, may have a higher temperature for the material requirements; some sports equipment, seals, and other non-motorized hand sets, low-temperature resistance to the material required (temperature not harden).

Chemical weathering requirements:

Some TPE, TPR products long-term outdoor use, for weathering and aging resistance have higher requirements; some industrial use, automobile use TPE, TPR products, may for chemical resistance (solvent resistance, chemical resistance) have higher requirements ʱ??

Processing condition selection:

TPE commonly used injection molding, extrusion or calendering molding and other processing methods. But overmolding (also known as plastic bag, the second injection, two-color molding, overmolding, etc.) is also a very common and important processing methods. According to the customer's product, its processing methods need to know whether the adhesive-coated molding.

TPE material, how to choose to be here today to share, in addition to the requirements described above, according to the specific product requirements need to choose the right kind of breakdown and require high flexibility and high wear resistance of soft products, recommend the use of soft TPU class, low hardness and elastic soft, optional silicone, also optional customized TPE soft.

Recommended Products