Service技术问答

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > Service

TPE material how to clean mold and the screw after refueling?

2015-09-10 10:19:19 admin

A lot of friends in the future use of TPE material injection molds need to be replaced and the cleaning of the screw, in order to ensure the continued operation of the next production, then the TPE material when the injection is completed refueling how to mold and screw replacement and cleaning it?Tryout mode conversion, wash-Code

To save TPE materials will minimize the amount of plastic head, now make the following procedures and washing machine codes.

I. beer sufficient in quantity, forwarding mode, be sure to shut down before the hopper, the TPE material within the beer barrel finish, straight beer can not back feed to screw up

II. When the change TPE material sure to dig a clean pail of material.

III. Beer black or dark gray plastic material empty shot put glue pressure is small, mash, available on the outlet together recycling.

IV. Outlet, defective and can not be recycled must be separated plastic head mounted.

V. holding seats sanitation and clean, try not to fall into the machine at the end outlet and defective, ground, mixed, contaminated.

VI. Beer before opening the mold surface oil, anti-rust oil wipe clean, avoid contaminated defective cause can not be recycled.

VII. Before the first washing machine powder in the hopper than expected to clean up dust and then washing material washing machine screw barrel, screw cleaning agent or detergent is added when necessary. Cleaning is almost complete before the renewal gradually lowered the barrel temperature can not return to feed material to avoid the barrel of the screw within the charred and melted into liquid again lead to open when beer.

VIII. You can use the white and transparent PP for cleaning.

X. Normally white beer after beer next turn gray, black, all without washing machine.

XI. Beer TPE down when no more than 15 minutes, do not shoot again when empty plastic beer. The beer was adjusted to about finished melt glue with glue, shot empty plastic beer when the test three times to open beer.

TPE barrel cleaning method:

1. screw or injection machine commonly used method for cleaning a direct refueling.

2. Transition refueling cleaning method.

- Previous:How TPE materials reduce shrinkage?

- Next:no

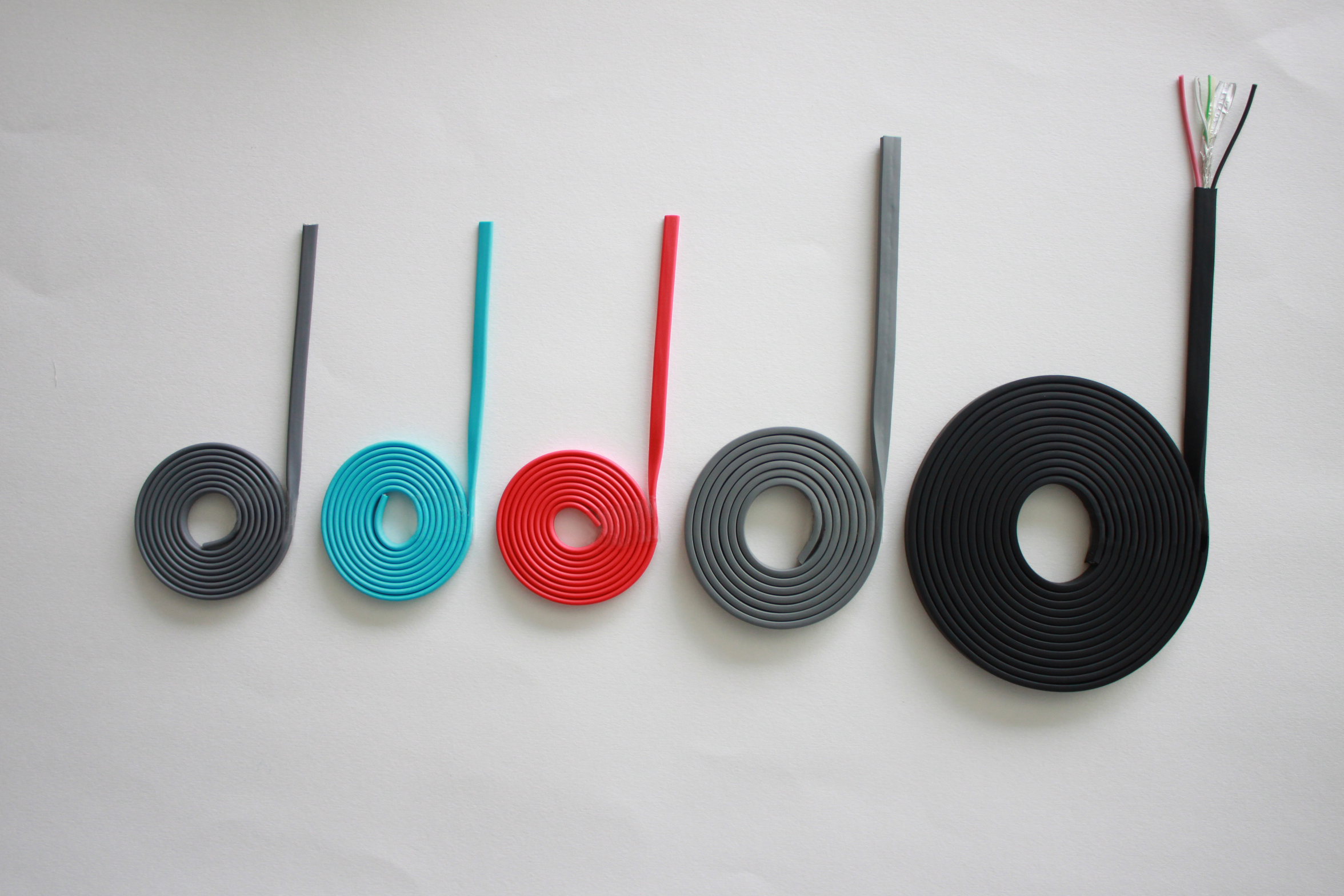

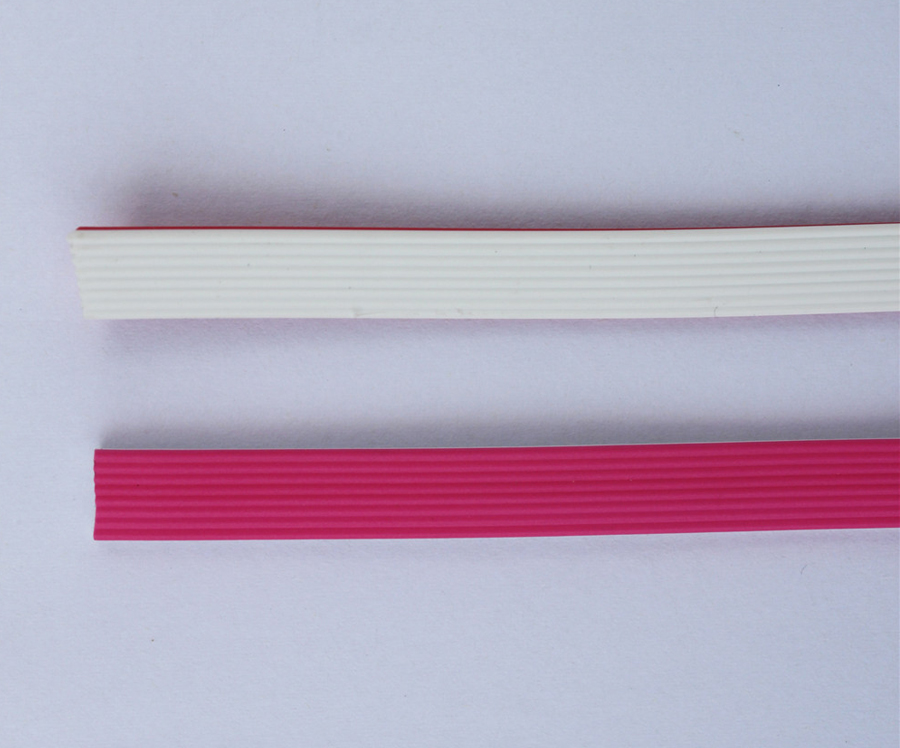

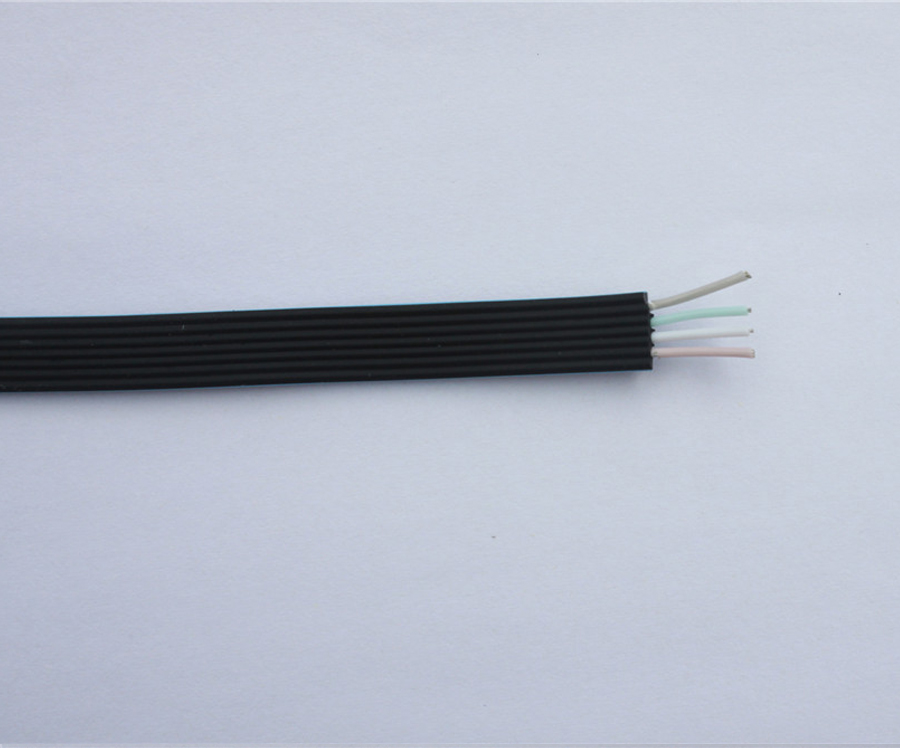

Recommended Products