Service技术问答

Honor荣誉资质

Contact联系我们

Free service hotline135-1047-0297

Phone: 86-0755-36697120

Fax: 86-0755-36697121

Phone: 135-1047-0297

Address: Shenzhen Komeito streets of Hong Fumin Industrial Park Liantang Village Fifth Building

Home > Service

TPE injection molding machine overheating causes and treatment

2015-09-10 10:11:09 admin

This article forwarded from TPE forum, but the method is indeed very easy to use, there are many recent customers using the injection molding machine production TPE product, some problems, we can refer to. TPE injection molding machines in use in the process, the machine may occur such problems, where temperature is relatively common today to help everyone to find the temperature rise causes and treatment methods:Common causes of elevated temperature TPE injection molding machines include the following:

(1) injection molding machine tank capacity is too small, not enough heat dissipation area, small cooling system capacity.

(2) press the fast forward speed selection quantitative pump oil pump capacity system, the excess will flow from the relief and fever overflow back at work under high pressure.

(3) system unloading circuit malfunction or because unloading circuit is not set, the pump does not stop working when unloading the entire flow of the pump under pressure overflow, overflow losses and heat generation, resulting in overheating.

(4) The system piping too small for too long, curved too much, most of the pressure loss and the pressure loss along the way.

(5) lack of precision components and poor quality of assembly, mechanical friction losses relative motion between.

With the gap (6) fitting is too small, or after use abrasion gap is too large, the inner and outer leakage volume, resulting in loss of large volume, such as reducing the volumetric efficiency of the pump, the temperature rise fast.

(7) to adjust the hydraulic system pressure is much higher than the actual need. Sometimes because of sealed tight, or because of damage to the seals, leakage increases have raised the pressure to work.

(8) The climate and operating environment temperature is high, resulting in temperature rise.

(9) the inappropriate choice of the viscosity of the oil, the viscosity is too large too small can cause fever, high temperature.

Approach:

1. Depending on the load requirements, always check and adjust the pressure relief valve.

2. A reasonable choice of hydraulic oil, especially oil viscosity, under the conditions permit, the use of low viscosity that reduce the friction caused by the viscosity losses.

3. To improve the lubrication conditions improve moving parts to reduce friction loss, help to reduce the workload and reduce fever.

4. To improve assembly quality hydraulic components and hydraulic systems with its own precision, tight fitting with the gap control and improved lubrication conditions, low coefficient of friction sealing materials and improved sealing structure, to minimize starting force of the hydraulic cylinder to reduce mechanical friction losses generated heat.

5. If necessary, additional cooling device

This is just a list of some common situations and treatment, if there is any other good way, I hope you continue to add users

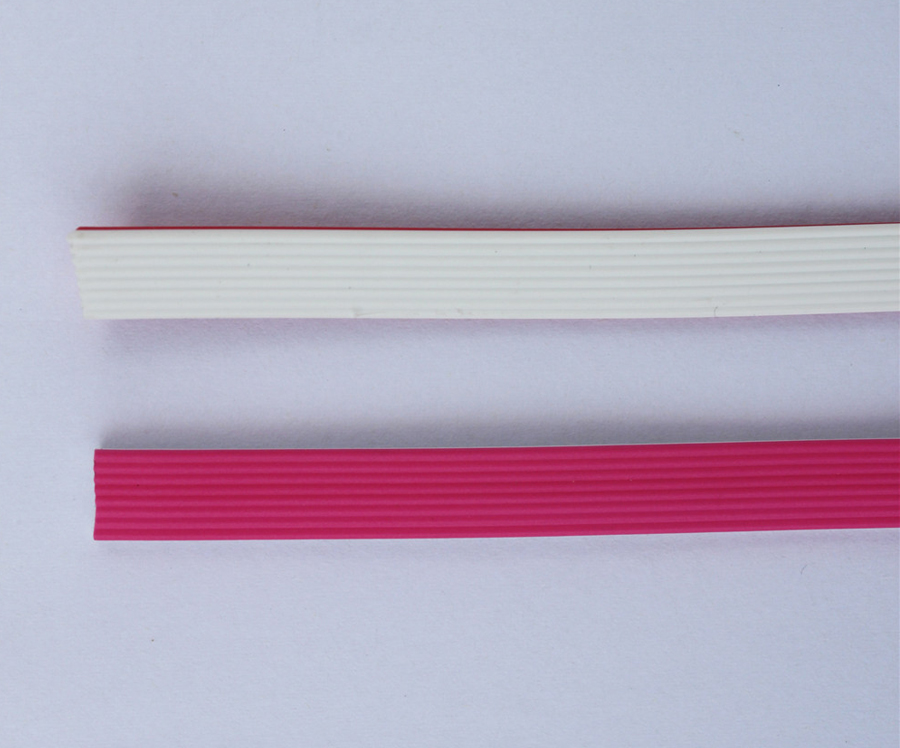

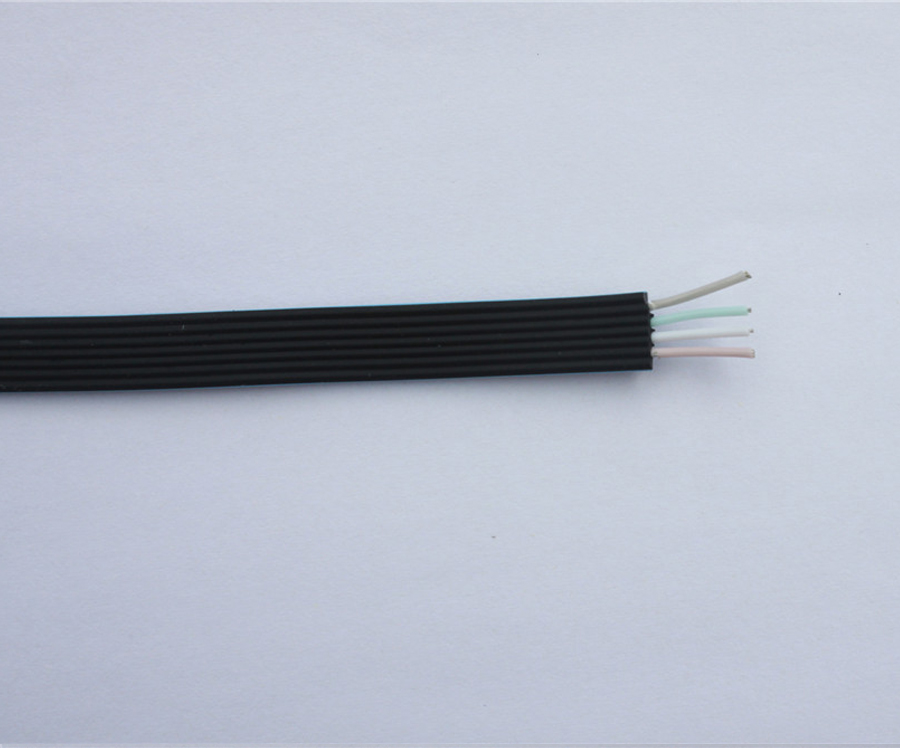

Recommended Products